In the realm of protective packaging, anti-static bubble bags stand as a beacon of innovation. These specialized materials are not merely about safeguarding fragile items; they offer a sophisticated solution to electrostatic discharge (ESD) threats. Yet, one question often arises: How resilient are these bags when it comes to puncture resistance?

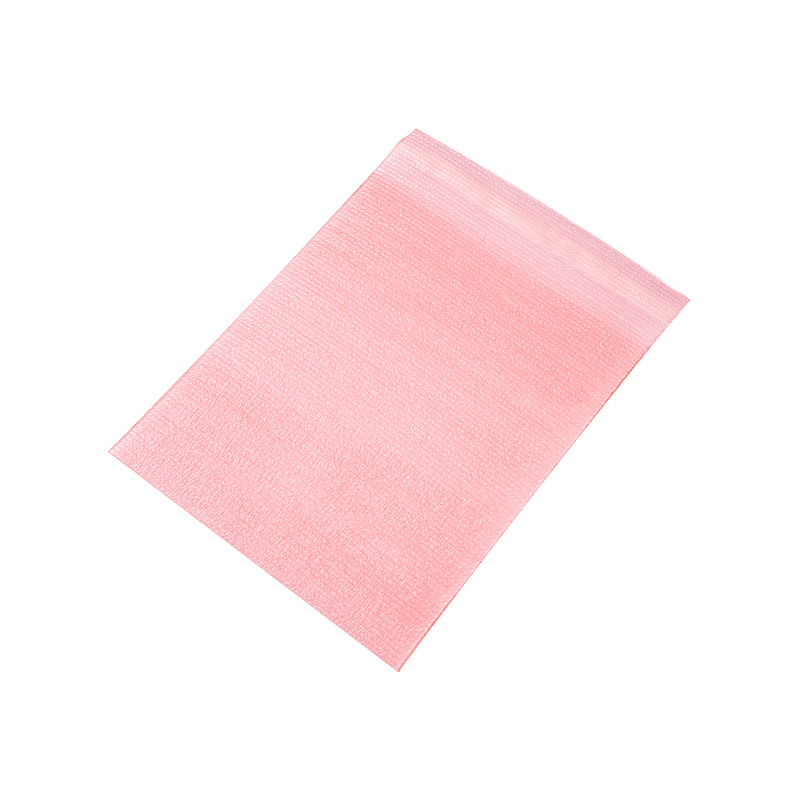

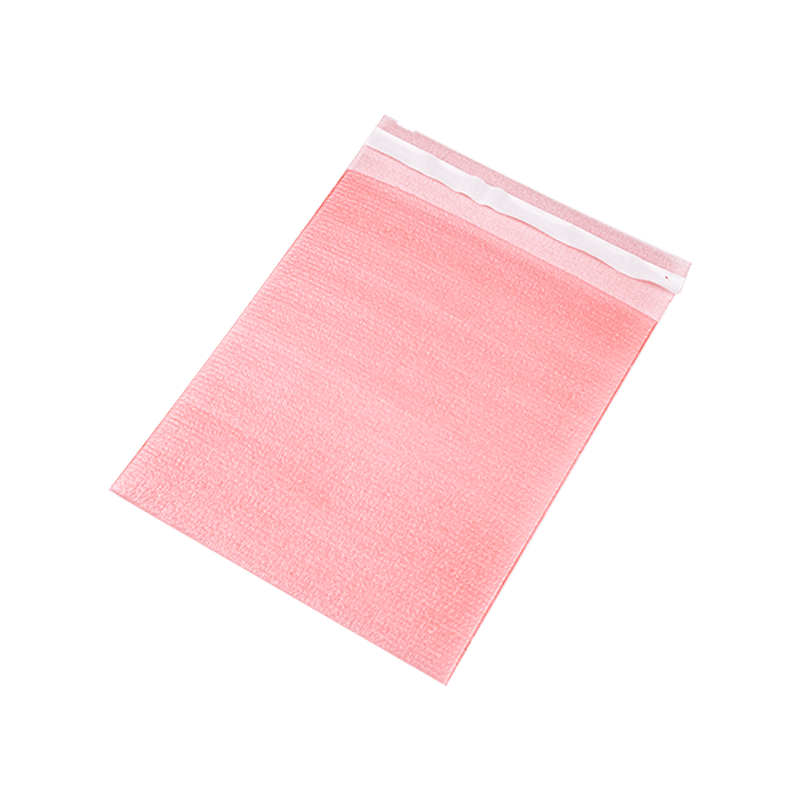

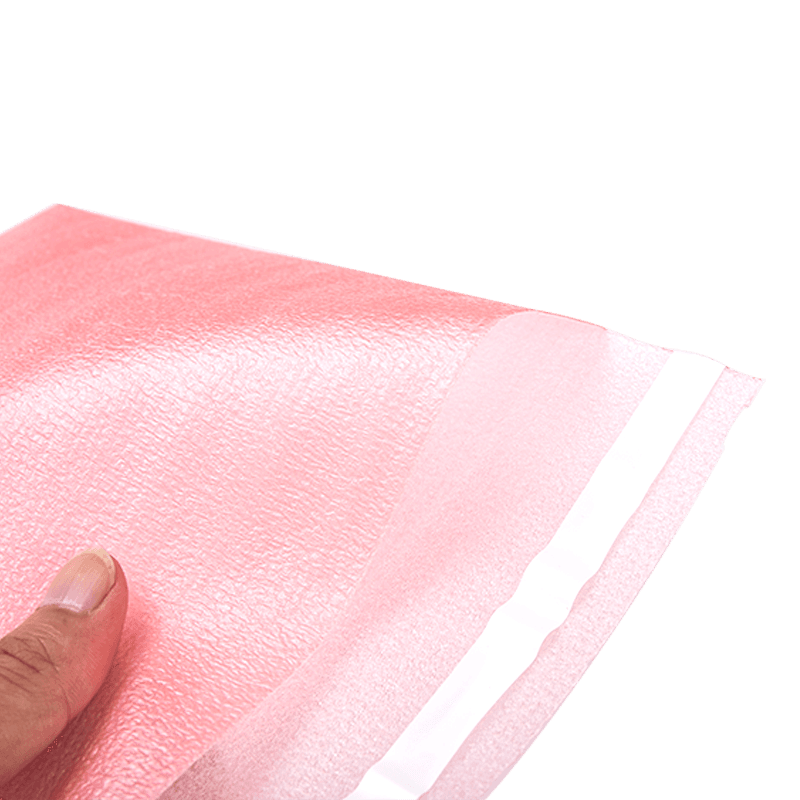

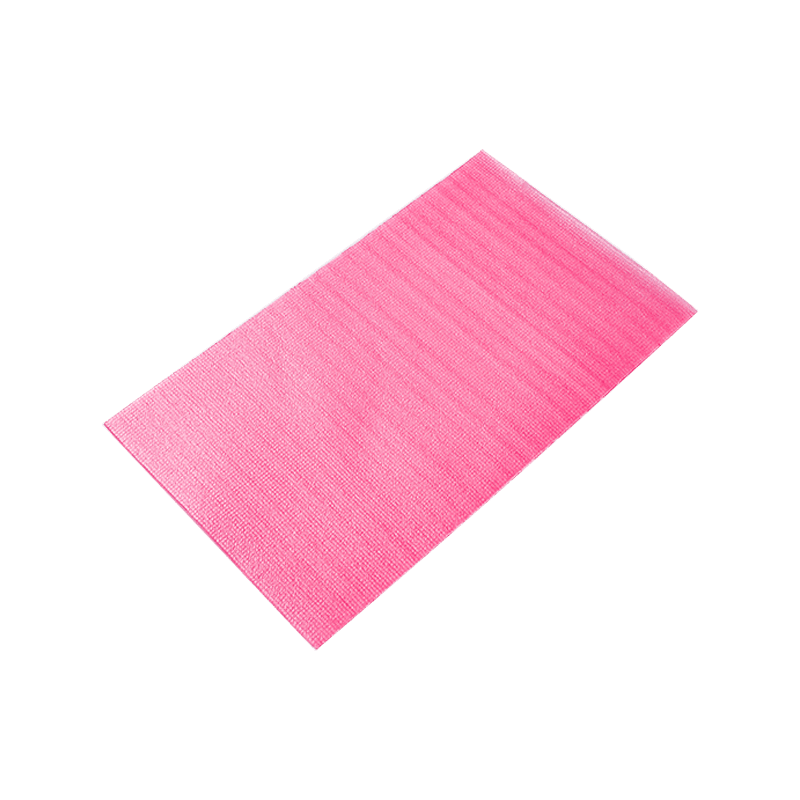

The answer lies in their intricate design and advanced material composition. Anti-static bubble bags are crafted with a dual-layered structure, where an inner layer of air-cushioned bubbles is encased within an outer shield imbued with anti-static properties. This unique architecture ensures both physical and electrostatic protection. However, puncture resistance is not solely contingent on this layered approach—it hinges on the quality of the materials employed.

High-density polyethylene (HDPE) or low-density polyethylene (LDPE) often forms the backbone of these bags. These polymers are lauded for their tensile strength and elasticity, attributes that significantly bolster puncture resistance. The interplay of molecular density and structural integrity creates a formidable barrier against sharp objects or abrasive surfaces. Moreover, the bubble layer itself acts as a shock absorber, dissipating force across its surface and further reducing the likelihood of breaches.

To quantify puncture resistance, one must delve into standardized testing protocols. Metrics such as grams of force required to penetrate the material provide empirical insights. Anti-static bubble bags typically exhibit impressive thresholds, often surpassing conventional packaging materials. This resilience ensures that sensitive electronics, medical devices, or precision instruments remain unscathed during transit.

However, the narrative does not end with material science alone. Environmental factors also play a pivotal role. Temperature fluctuations, humidity levels, and exposure to corrosive substances can subtly erode the bag's robustness over time. Thus, selecting a product engineered for diverse conditions is paramount.

For businesses seeking unparalleled protection, investing in premium-grade anti-static bubble bags is non-negotiable. These products often incorporate additional reinforcements, such as co-extruded layers or proprietary additives, which elevate puncture resistance to new heights. Such enhancements ensure that even under duress, the contents remain cocooned in safety.

The puncture resistance of anti-static bubble bags is a symphony of material ingenuity and meticulous engineering. They are not just packaging solutions but guardians of integrity, ensuring that delicate items traverse the supply chain unharmed. When selecting these bags, prioritize those that marry durability with anti-static prowess. After all, in the world of logistics, prevention is invariably superior to remedy.